WABCO Fault Codes - TruckManuals.com

Below is an in-depth list of some of the most commonly encountered WABCO Fault Codes. With this information you or your techs can quickly assess the problem and begin working on a solution. Looking for diagnostic software?

Read and understand all instructions and procedures before you begin to service components. Read and observe all Caution and Warning safety alerts that precede instructions or procedures you will perform. These alerts help to avoid damage to components, serious personal injury, or …

Some brake linings contain non-asbestos fibers, whose long-term effects to health are unknown. You must use caution when you handle both asbestos and non-asbestos materials. This publication provides instructions for diagnosing and repairing issues with the electronic brake system using TOOLBOXTM Software. WABCO Diagnostic Interfaces. 1.

ELECTRONIC if fault occurence repeats without brake squeezing. SID FMI Blink Code FAULT Universal pin/plug BASIC, pin/plug FRAME pin/plug Faultindication E-FRAME, E-Universal COMMENT (REACTION) Cause Action Wheel Sensor right front 2 1 3 + 1 air gap 10;13/18 10;13/18 5..6/x2 WL ABS: wheel disabled ASR, RSC, RSA: disabled

ABS is a system designed to provide and maintain the best possible traction and steering control during an extreme braking event. During a potential wheel lock event, the ABS ECU, using information provided by the wheel speed sensors,

This manual contains service, troubleshooting, and repair information for the WABCO Anti-Lock Braking System (ABS) and ABS with Automatic Traction Control (ATC) for trucks, tractors, and buses manufactured after December 1990. If your ABS-equipped vehicle was manufactured before this date, call WABCO

05-Fault Code List-Wabco | PDF | Anti Lock Braking System - Scribd

This document provides fault codes, descriptions, and recommended actions for an ABS-E braking system with ESC, RSC, and A features. It lists 13 fault codes for a left front wheel sensor, providing the ABS and system reactions, fault description, and …

Suspect ECU is at fault if the problem persists. 3. Measure the resistance between pin 7 of the X2 (black) connector and a good chassis ground. Repeat the test between pin 8 and ground. Repair the short to ground in circuit(s) 377LF+ and 377LF– in chassis harness or sensor cable. If problem is in sensor harness, replace the sensor. 3.

Read and observe all Warning and Caution hazard alert messages in this publication. They provide information that can help prevent serious personal injury, damage to components, or both. Follow your company’s maintenance and service, installation, and diagnostics guidelines.

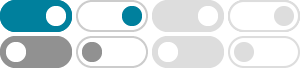

The WABCO Electronic Control Unit (ECU) uses a pattern of light flashes called a blink code to identify specific problems, or f aults, in the ABS. The warning lamp flashes a blink code for each fault that the ECU stores in its memory, enabling a technician to re pair