The Complete Guide to Zinc Plating: All You Need To Know

2024年5月14日 · And, zinc plating is one of those ways. Known to some as zinc electroplating or zinc galvanization, this process essentially involves applying a thin layer of zinc to the surface of a metal. The process is done via electroplating, and you achieve this by dropping the metal part in a zinc solution and adding an electrical current.

What is Zinc Plating: Process, Types, Colors and Specifications

2024年11月11日 · Zinc plating is a specific type of zinc coating achieved through an electroplating process, where a thin layer of zinc is deposited onto a metal surface. Zinc coating, however, can refer to any method of applying zinc, including hot-dip galvanizing and zinc-rich paints, which are different in thickness, application process, and corrosion ...

What Are The Different Types Of Zinc Plating? | Dorsetware Ltd

2021年8月5日 · Zinc electroplating is a method of metal plating that stops rust and corrosion. Read why this method is used world-wide and about the four types of zinc plating. Dorsetware Limited

Zinc Plating

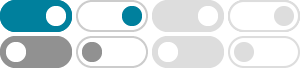

Zinc plating protects steel from red rust. Chromates protect the zinc coating from white rust. These are the two specifications that are called out for salt spray. All of our trivalent chromates are hexavalent free and comply with current REACH, ELV and ROHS Regulations. TP offers 3 chromate colors to suit your requirements. Clear Zinc

Eye-Catching Zinc Plating Colors: A Dazzling Visual Treat - Zintilon

2024年4月24日 · Below is an overview of the different types of zinc passivation color techniques. The zinc color technique involves immersing the substrate (mostly steel) in molten zinc at about 450°C (842°F). The zinc then bonds with the substrate. The post-treatment process involves immersing the zinc-plated part into a hexavalent chromium solution.

Zinc Plating: Everything you need to know - ProleanTech

2023年12月22日 · Zinc plating is used to tackle the rust formation problem by creating a thin barrier on the surface, preventing it from corrosion while reacting with the environment. In this article, we will go through the working of zinc plating, the steps involved, affecting factors applications, advantages, and limitations.

Industrial & Large Part Zinc Plating | Gatto Industrial Platers, Inc.

Zinc plating is a two- part electrolytic process that utilizes a current of electricity to deposit a thin layer of Zinc onto a parts surface. The zinc layer coats the part acting as a protective barrier against moisture and ultimately corrosion.

Zinc Plating: Essential Techniques and Applications - Hybrid Coating …

2024年6月14日 · Modern zinc plating still relies on the foundational principles developed centuries ago, but now includes specialized equipment like rectifiers and plating stations. These upgrades have allowed for more precise control over plating thickness and uniformity, ensuring consistent and high-quality results.

Different Color Types of Zinc Plating

2022年9月30日 · Here are a few of the most popular color options for zinc plating: Yellow/gold: Yellow/gold is one of the best color options because of its bright shine. It is a good option for those of you who want your parts to stand out. Clear/blue – Clear/blue is the perfect color to keep your zinc plating under wraps. Most people won’t even notice ...

Zinc Plating - American Galvanizers Association

The normal zinc-plated coating is dull gray in color with a matte finish, although whiter, more lustrous coatings can be produced, depending on the process or agents added to the plating bath or through post-treatments. The coating is thin, ranging up to 1 mil (25 µm), restricting zinc-plated parts to very mild (indoor) exposures.